Why Do I Need a Screw Conveyor?

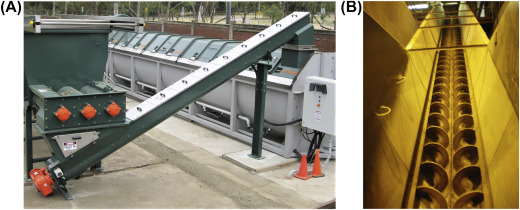

As a business owner running an industrial operation, you understand the importance of having reliable equipment and parts to help keep operations going smoothly. One essential piece of equipment that any efficient operation should have is a screw conveyor, also known as an auger conveyor. This blog post explores five reasons every business needs this conveyor type.

1. Versatility

Versatility is one of the greatest benefits of owning this type of conveyor. With applications in cement, timber, road construction, agriculture, and food processing industries, this flexible machine offers solid performance and workhorse dependability. It is also easy to use, with no vibration or noise pollution and minimal maintenance needed.

Additionally, it can be custom-made to individual specifications for unique operations and adjusted based on the nature of the material being conveyed — ideal for conveying sand, loose grain, or even snow. Furthermore, it has an enclosed inner area, so materials remain clean and sweat-free during transit.

2. Efficiency

Efficiency is one of the main reasons why an auger conveyor may be necessary. The screw moves dry material effectively, meaning it can help streamline business processes to reduce labor costs and increase productivity. Furthermore, auger conveyors are made from corrosion-resistant materials, which helps ensure their long-term performance and reduces maintenance costs associated with other conveyors.

Its low energy consumption and quiet operation are cost-effective alternatives for bulk material movement in many industries. Finally, because these conveyors are simpler than other models, they are easier to install and maintain with minimal disruption to overall operations.

3. Space-saving

Space-saving is another benefit of this type of conveyor. Installing an auger conveyor in your facility saves considerable space compared to other conveyors. The screw conveyor compact design and ability to move product in multiple directions makes it ideal for tight areas with limited space.

In addition, it can handle greater volumes of the product than other types of conveyors and reduces the need for additional storage space due to its efficient handling. Finally, its rotating motion creates far less vibration than traditional belt-based designs, which also helps to reduce overall noise levels.

4. Cost-effective

Another reason why you need this type of conveyor is its cost-effectiveness. An auger conveying system has several key benefits, such as its affordability and scalability. As it is relatively affordable compared to other conveyors, it provides customers with cost efficiencies they cannot elsewhere.

Additionally, businesses can start small and expand their auger conveyor system if needed. Finally, another reason why investing in this conveyor is that these machines require minimal maintenance, making them extremely reliable for transporting goods quickly and affordably.

5. Customizable

The screw’s flexible design makes it perfect for various materials and tasks, from transporting large objects in industrial settings to handling delicate products that require careful handling. It can fit even the most complex layouts, allowing you to configure it to fit your space requirements best.

Additionally, the parts are interchangeable for easy maintenance, allowing you to quickly repair any issue without purchasing all new components. With its customizable options and automated functionality, an auger conveyor is ideal for virtually any situation.

Considering the benefits of having a screw conveyor helps you make an informed decision about whether or not one is right for your business needs. As always, consult a professional to get started and learn more about what system works best for you.