What Is Pre-Insulated Ductwork and How Does It Work?

Efficient heating, ventilation, and air conditioning (HVAC) systems rely on ductwork that minimizes energy loss while ensuring consistent airflow. Traditional duct systems often require on-site insulation installation, which can be time-consuming, labor-intensive, and prone to errors. To overcome these challenges, pre-insulated ductwork has become increasingly popular in both commercial and residential HVAC projects. This innovative solution offers improved thermal efficiency, quicker installation, and long-term durability compared to conventional duct systems.

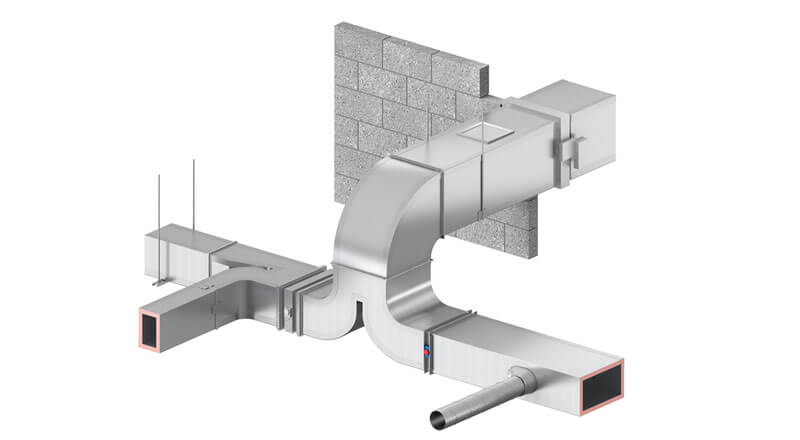

Pre-insulated ductwork refers to duct systems that come with insulation already applied during the manufacturing process. Instead of adding insulation on-site, these ducts are produced with a layer of insulating material bonded to the exterior of the duct, often accompanied by a protective outer jacket. This ensures that the ducts are ready for installation immediately upon delivery, reducing the time and labor required on-site. Manufacturers offering solutions like pre insulated ductwork allow contractors to streamline their workflow while maintaining high-quality insulation standards. The integration of insulation during production also ensures uniform coverage and minimizes potential gaps or thermal bridges that could compromise system efficiency.

Components of Pre-Insulated Ductwork

Pre-insulated duct systems are typically composed of three primary layers: the inner duct, the insulation layer, and the outer protective jacket. The inner duct, usually made of galvanized steel or aluminum, serves as the conduit for air movement. Surrounding the inner duct is a layer of thermal insulation, commonly polyurethane foam or mineral wool, which reduces heat loss or gain and maintains consistent temperature within the airflow. Finally, the outer jacket, often made of aluminum or PVC-coated material, protects the insulation from moisture, physical damage, and environmental wear. These three components work together to provide a duct system that is both thermally efficient and mechanically robust.

How Pre-Insulated Ductwork Improves Energy Efficiency

The insulation in pre-insulated ducts prevents heat transfer between the air inside the duct and the surrounding environment. During heating or cooling operations, this insulation reduces the loss of conditioned air, ensuring that the air delivered to rooms or spaces is at the desired temperature. By minimizing energy losses, pre-insulated ducts help HVAC systems operate more efficiently, lowering energy consumption and reducing utility costs. Additionally, effective insulation reduces condensation on the duct surface, which can help prevent mold growth and maintain indoor air quality.

Installation Advantages

One of the most significant benefits of pre-insulated ductwork is simplified installation. Since the ducts come with insulation pre-applied, workers no longer need to wrap or attach insulation on-site. This reduces labor costs and accelerates project timelines. The consistent thickness and quality of factory-applied insulation also eliminate the risk of uneven coverage, which can occur with manual installation. Contractors can assemble duct systems more quickly and with greater confidence that the thermal performance will meet design specifications.

Noise Reduction Benefits

Beyond thermal performance, pre-insulated ductwork also contributes to acoustic control. The insulation layer dampens vibrations and reduces noise generated by air movement or mechanical equipment. This feature is particularly valuable in commercial buildings, hospitals, and schools where quiet indoor environments are essential. By combining insulation and duct design, pre-insulated systems offer an effective solution for both energy efficiency and noise management.

Durability and Maintenance

Pre-insulated ducts are designed to last for many years with minimal maintenance. The protective outer jacket shields the insulation from moisture, dust, and physical damage, ensuring that the ducts remain effective even in challenging environments. Unlike traditional ducts, which may require periodic inspection and re-insulation, pre-insulated systems provide consistent performance over time. This durability translates into lower long-term maintenance costs and a longer service life for the HVAC system.

Customization and Flexibility

Modern pre-insulated duct systems are highly customizable to meet specific project requirements. Manufacturers can produce ducts in various shapes, sizes, and insulation thicknesses to accommodate different building designs and airflow requirements. Flexible joints, bends, and transitions can also be included in the pre-insulated design, making installation easier in complex layouts. This adaptability allows engineers and contractors to implement energy-efficient solutions without compromising design flexibility.

Environmental and Sustainability Considerations

Pre-insulated ductwork also contributes to sustainability goals by improving energy efficiency and reducing the carbon footprint of HVAC systems. Lower energy consumption directly translates to reduced greenhouse gas emissions associated with heating and cooling. Additionally, the precision manufacturing process minimizes material waste compared to on-site insulation methods. Some insulation materials used in pre-insulated ducts are also environmentally friendly, further enhancing the system’s green credentials.

Conclusion

Pre-insulated ductwork offers a modern solution to the challenges of traditional HVAC duct systems. By combining factory-applied insulation with durable construction, these ducts improve energy efficiency, reduce installation time, enhance acoustic performance, and provide long-term durability. Their flexibility and customization options make them suitable for a wide range of commercial and residential applications. As energy efficiency and sustainability become increasingly important in building design, pre-insulated duct systems are poised to play a critical role in delivering high-performance HVAC solutions.