3D Printing for Product Design: Benefits and Uses

As the manufacturing world continues to evolve and technology becomes more advanced, new product design methods are constantly emerging. 3D Printing is one such method that has revolutionized product design by enabling faster prototyping. 3D printing has revolutionized product design, creating complex shapes and designs previously impossible to produce. Additive manufacturing technology has made it possible to produce custom-designed products and has opened up new possibilities for mass customization. 3D printing is also becoming increasingly affordable, making it a viable option for small businesses and individual designers.

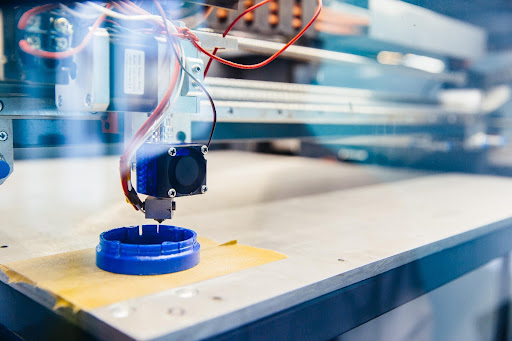

Applications of 3D Printing for Product Design

Concepting

There are many leverages to using 3d printing services for product development. It allows you to create a three-dimensional product that can be used for various purposes. It allows you to quickly and cheaply create prototypes of your products, which can be used for testing and marketing purposes. Additionally, it allows you to customize your products, making them unique and more attractive to customers. And finally, it enables you to manufacture small batches of your products without needing large-scale production facilities or expensive tooling.

Prototyping

Product prototyping with 3d print technology can help you quickly and affordably create a working model of your product idea. 3d printing lets you create complex shapes and structures which can be tough or impossible to create using traditional manufacturing methods. You can create a prototype of your product in just a few hours and iterate on your design quickly and easily with a 3d printer.

Quickly create and trial prototypes of your product and make changes to your design before committing to expensive tooling or manufacturing processes. If you’re looking to bring your product idea to life, 3d printing in Sydney is a great place to start.

End-Use Production

3D printing is playing an increasingly important role in end-use production. This means that products are made directly from a digital file without intermediate steps. This technology offers several advantages over traditional manufacturing methods, including the ability to produce complex geometries, reduced lead times, and lower tooling costs. This technology is particularly well-suited for small batches or custom production, as there is no need for expensive tooling or molds. This can result in significant cost savings for manufacturers.

Benefits of 3D Printing in Product Design

Improved Workflow

3D printing technology has allowed for a more efficient workflow in product design. In the past, designers had to rely on 2d drawings and prototypes to test their designs. With 3D printing, designers can quickly and easily print out their designs and test them in the real world. This allows for a much faster design process and helps ensure that products are high quality before they go into production. This can save time and money in the long run by reducing the need for multiple rounds of prototyping and manufacturing.

Reduced Costs

3D printing can help reduce costs in product design in several ways. First, it can enable designers to quickly and cheaply prototype new designs. This can help reduce the cost of developing new products and the cost of making changes to existing products. Additionally, 3D printing can produce custom product parts or components, leading to reduced production costs. Finally, 3D printing can create end-use products, eliminating the need for costly tooling and other manufacturing processes.

Image Source: Freepik.com

Better Testing and Freedom

3D printing can be used to create prototypes of products before they are put into production. This allows for better testing and development and the potential for customization and personalization. This is the best way to test and trial new designs and ideas without investing in expensive tooling or manufacturing processes. Additionally, 3D printing allows you to create complex shapes and geometry which is impossible to produce using traditional methods. Overall, better product testing and freedom with 3D printing can lead to improved products and faster innovation. So, if your company is not already using this technology, it may be worth exploring.

3D print is a major tool for industrial product design. It allows designers to create prototypes and products with intricate designs that would be difficult or impossible to create using traditional manufacturing methods. 3D printing also offers the advantage of producing small batches of custom products, which can be helpful for companies that need to test out new designs before mass-producing them.

FAQ

Can 3D printing be used for production?

3D printing is a promising production technology, but some challenges still need to be addressed before it can be widely adopted.

What role is 3D printing play in design and production?

3D printing plays a significant role in design and production, particularly in prototyping. 3D printing allows designers and engineers to quickly and easily create prototypes of their products, which can then be tested for form, fit, and function before moving on to full-scale production. This can save significant time and money in the product development process. Additionally, 3D printing is increasingly used to produce final products, particularly in niche markets where traditional manufacturing methods are not well suited.