Understanding Swing Type Check Valves: Applications and Benefits

Swing type check valves are essential components in fluid systems, providing a simple yet effective mechanism to prevent backflow and ensure the proper direction of fluid flow. With their unique design, these valves play a critical role in maintaining the efficiency, safety, and longevity of various industrial processes. This article delves into the applications and benefits of swing type check valves, explaining why they are a preferred choice in numerous fluid control systems.

What is a Swing Type Check Valve?

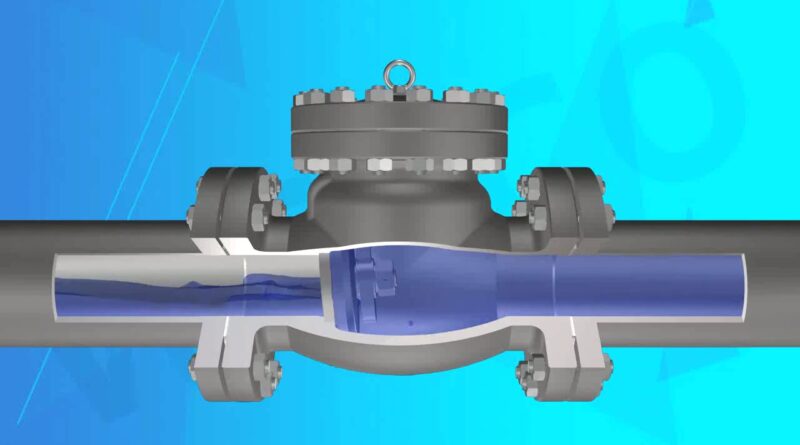

A swing type check valve is a mechanical valve that allows fluid to flow in only one direction. It consists of a valve body, a hinged disc (or swing), and a seat. The disc swings open when fluid flows in the forward direction and closes when the flow reverses, preventing backflow. This type of valve is typically used in systems where the flow direction is critical and where the protection of equipment from reverse flow is necessary.

Applications of Swing Type Check Valves

Swing type check valves are widely used in various industries, including:

1. Oil and Gas Industry

In the oil and gas sector, maintaining the integrity of pipelines and equipment is paramount. Swing type check valves are used to prevent backflow that could damage pumps, compressors, and other essential machinery. These valves ensure that the flow of oil, gas, or other fluids remains unidirectional, preventing costly damages and ensuring smooth operations.

2. Water and Wastewater Treatment

Water and wastewater treatment facilities often rely on swing type check valves to protect pumps and prevent contamination. These valves ensure that treated water or wastewater flows in the intended direction and doesn’t flow backward into the system, which could lead to contamination and operational inefficiencies.

3. Power Generation

In power plants, swing type check valves are critical in maintaining proper flow direction in steam and water systems. These valves prevent backflow that could disrupt the functioning of critical equipment such as turbines, boilers, and condensers. By ensuring that fluid only flows in the correct direction, swing check valves help enhance the efficiency and safety of power generation systems.

4. HVAC Systems

Swing type check valves are often used in heating, ventilation, and air conditioning (HVAC) systems to control the flow of refrigerants and fluids. These valves protect the system from backflow that could cause damage to compressors, filters, and other vital components, ensuring the HVAC system runs smoothly and efficiently.

5. Food and Beverage Processing

In the food and beverage industry, swing type check valves are employed to maintain the integrity of the fluid flow in processing systems. These valves help prevent cross-contamination and ensure that fluids flow in the correct direction, thereby enhancing food safety and product quality.

Benefits of Swing Type Check Valves

Swing type check valves offer numerous advantages in fluid control applications, making them a popular choice for many industries. Here are some of the key benefits:

1. Simple and Reliable Design

Swing type check valves are known for their simple yet effective design. The valve body, swing disc, and seat create a straightforward mechanism that reliably prevents backflow. This simplicity makes them less prone to malfunction compared to more complex valve types, ensuring consistent performance over time.

2. Cost-Effective

The relatively simple construction of swing type check valves makes them a cost-effective choice for a wide range of fluid systems. Compared to more intricate valve designs, swing type check valves are generally less expensive, both in terms of initial investment and long-term maintenance. Their durability also reduces the need for frequent replacements, making them a budget-friendly solution.

3. Low Maintenance Requirements

Swing type check valves are designed for long-lasting performance with minimal maintenance. Their robust construction and straightforward operation mean that they are less likely to fail due to wear and tear. Regular inspections are typically sufficient to ensure their continued functionality, making them a low-maintenance option for industrial applications.

4. Efficient Backflow Prevention

The primary function of a swing type check valve is to prevent backflow, and it does so efficiently. When reverse flow is detected, the disc swings shut, creating a tight seal that stops the fluid from flowing backward. This prevents contamination, protects equipment, and ensures the safe operation of fluid systems.

5. Versatility

Swing type check valves can be used in a variety of applications, from handling liquids to gases, in different industries. Their versatility makes them suitable for a wide range of operating conditions, including high and low pressures, varying temperatures, and a diverse range of fluids. This adaptability ensures that they remain an essential tool in many fluid control systems.

6. Enhanced Flow Capacity

Swing type check valves are designed to provide minimal flow resistance, allowing fluids to pass through them with ease. The smooth, unrestricted flow minimizes pressure drops and optimizes system efficiency. This makes swing check valves ideal for high-flow applications, where maintaining an efficient flow rate is critical.

7. Easy Installation

Due to their simple construction and design, swing type check valves are relatively easy to install in a variety of fluid systems. Their compact design ensures that they can be integrated into existing setups with minimal modification, making the installation process quick and efficient.

Considerations for Choosing Swing Type Check Valves

While swing type check valves offer many benefits, it is essential to consider certain factors before selecting them for an application:

- Installation Orientation: Swing check valves are generally installed in horizontal pipelines. However, they can also be used in vertical pipelines with upward flow, but installation orientation should always be considered to ensure optimal performance.

- Fluid Type: Swing type check valves are suitable for many fluids, but the type of fluid (such as abrasive, corrosive, or high-viscosity fluids) should be taken into account to ensure compatibility with the valve materials.

- Pressure and Temperature: Understanding the pressure and temperature conditions in which the valve will operate is crucial for selecting the right material and ensuring the valve’s performance over time.

Conclusion

Swing type check valves are an indispensable component in fluid systems across various industries, providing reliable backflow prevention and precise flow control. Their simple design, low maintenance, and cost-effectiveness make them an attractive choice for many applications, from oil and gas pipelines to water treatment plants. By ensuring that fluid flows in the intended direction, swing type check valves help protect equipment, prevent contamination, and improve the overall efficiency of industrial processes. When considering backflow prevention solutions, swing type check valves offer a durable and versatile option that meets the demands of numerous industries.