Production Processes Used in a Press Machine Factory

Press machines play a vital role in modern manufacturing, enabling industries to perform metal forming operations such as stamping, punching, bending, and drawing. The production of these machines requires a combination of engineering expertise, precision machining, and strict adherence to quality standards. A press machine factory follows a structured sequence of production processes to ensure that each machine meets the required performance, safety, and durability standards. From design to final inspection, every step is carefully managed to deliver reliable and efficient equipment.

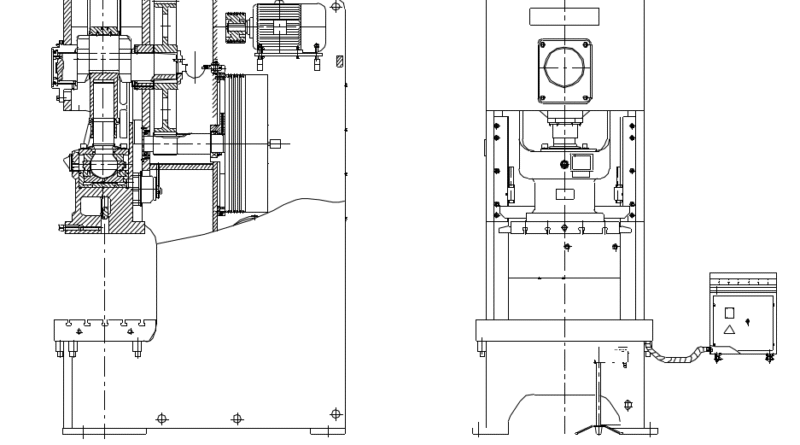

The production process begins with detailed engineering and design. Engineers use computer-aided design (CAD) software to create precise schematics, ensuring that the machine will meet operational requirements and safety standards. Material selection is determined at this stage, with high-strength steel, alloys, and specialized components chosen for durability and performance. A reputable Press Machine Factory ensures that all materials comply with international quality standards, providing a solid foundation for the manufacturing process. Proper planning at this stage reduces the likelihood of errors during fabrication and assembly, improving overall efficiency.

Component Fabrication and Machining

Once the materials are selected, the factory moves to component fabrication and machining. This stage involves transforming raw materials into precise parts such as frames, rams, gears, shafts, and die holders. Advanced CNC (Computer Numerical Control) machines are often used to achieve high levels of precision and repeatability. Machining processes may include cutting, drilling, milling, turning, and grinding, with close attention to dimensional tolerances. Accurate machining is critical, as even small deviations can affect the machine’s performance and safety.

Surface treatments are often applied after machining to enhance durability and resistance to wear and corrosion. Components may undergo heat treatment, polishing, or coating processes depending on their role in the machine. Each part is inspected for quality, and defective components are removed before assembly to maintain production standards.

Assembly of Press Machines

The assembly process brings all fabricated components together to form a complete press machine. Skilled technicians align and fit critical parts such as the ram, bed, and die holder to ensure proper functioning and uniform force distribution. Alignment is crucial to prevent uneven wear, maintain accuracy in metal forming, and enhance the longevity of the machine.

Electrical and hydraulic systems are integrated during assembly. Motors, sensors, switches, and safety devices such as guards and interlocks are installed and tested to guarantee operational safety. Modern press machines often include automation features for enhanced productivity, requiring careful integration of electronic control systems during assembly.

Testing and Calibration

After assembly, each press machine undergoes rigorous testing and calibration. Functional tests simulate real-world operating conditions to verify that the machine performs accurately, consistently, and safely. These tests include measuring stroke, pressure, speed, and alignment of the ram, as well as evaluating hydraulic or mechanical system performance. Safety systems, such as emergency stops, interlocks, and protective guards, are also tested to ensure proper operation.

Calibration ensures that the machine operates within its specified tolerances. Proper calibration is essential for precision tasks such as stamping and punching, where accurate alignment and force application directly impact the quality of the produced components.

Quality Control and Final Inspection

Quality control is integrated throughout the production process and culminates in a final inspection before the machine is delivered. Inspectors check the alignment, structural integrity, surface finish, and functional performance of each component. Any irregularities are corrected, and final documentation is prepared, including material certifications, test results, and operational manuals. These records ensure traceability and provide customers with confidence in the reliability and safety of the machine.

Maintenance Guidelines and Operator Training

A professional press machine factory also provides maintenance instructions and operator training. Preventive maintenance schedules, lubrication requirements, and safety protocols are outlined in detailed manuals. Training may include on-site instruction to ensure operators understand how to use the machine safely, identify potential issues, and perform basic troubleshooting. Proper maintenance and training extend the machine’s operational life and reduce the risk of accidents.

Continuous Improvement and Innovation

Many press machine factories implement continuous improvement programs to enhance production efficiency and machine performance. Feedback from customers, technological advances, and operational monitoring help identify areas for enhancement. Modern innovations such as IoT-enabled monitoring systems, robotic integration, and automation improve both production consistency and safety. By continuously updating processes and designs, factories maintain a competitive edge while ensuring high-quality products.

Conclusion

The production processes in a press machine factory involve multiple coordinated stages, from design and material selection to machining, assembly, testing, and final inspection. By following strict quality control measures and incorporating advanced technology, manufacturers ensure that every machine meets operational, safety, and durability standards. A reliable Press Machine Factory focuses on precision, quality, and operator safety, providing customers with equipment that performs consistently and reliably. These comprehensive processes make press machines indispensable tools for industrial metal forming, supporting efficiency and productivity across diverse manufacturing sectors.