DTF Printer Consumables – A Different Kind of DTF Films

In today’s printing technology, white ink hot stamping printer consumables play an increasingly important role. Among them, white ink hot stamping film, as one of the essential printing consumables, makes the concept of personalized customization more deeply rooted in people’s hearts by virtue of its excellent performance and diversified features. There will also be more people to choose the white ink stamping machine with market potential. In this article, we will discuss the characteristics of DTF films and its application flash point in the printing field.

General characteristics of DTF films:

Strong weather resistance: the film has good weather resistance, even after a long time of outdoor exposure, the color will not easily fade or fade.

Strong adhesion: the DTF PET films has good adhesion, can form a strong adhesion on the surface of various materials, to ensure that the printed image will not be easily peeled off or damaged.

Environmentally friendly and non-toxic: DTF transfer films does not contain substances harmful to the human body and the environment, in line with environmental requirements.

Wide range of application: DTF films is suitable for all kinds of white ink stamping printers, good compatibility and easy to operate.

What you should pay attention to when selecting transfer films is: whether the coating is even with thickness. In the early PET film just listed into use, found that the uncoated side is easy to slip, easy to cause the phenomenon of poor printing results. Now basically the market are double-sided coating film, effectively reducing the problem of sliding misalignment.

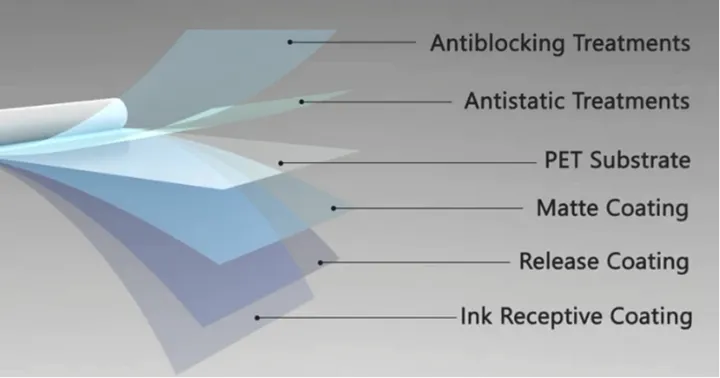

The structure of DTF PET film can be clearly understood from the following figure

DTF films are produced on a base layer of PET material coated with a release layer and an ink-absorbing layer. High-quality films add a backside coating to realize anti-static and anti-adhesion continuous processing.

There are two types of DTF films, hit-and-tear and cool-tear films. There is no difference between hot and cold tearing, it just depends on the customer’s usage habits.

DTF transfer film has a variety of visual effects, which can support the personalization of many types of garments. For example: 3D water cube film, temperature change film, dazzling reflective film, laser film, luminous film, flash film, glow-in-the-dark film, high-gloss reflective film, hot-stamping film, hot-stamping silver film and so on.

3D water cube film has a kind of three-dimensional sense of Rubik’s Cube and the sense of flow, seems to be on land, but has a kind of visual effect of swimming in the water. Good transfer effect, no residue.

Temperature change film is different according to the temperature, generally below 29 ℃ will show a dull black and gray, greater than 32 ℃ or more, it will show the original design. With different color effects. This kind of garment is very suitable in summer and winter season.

Dazzle reflective film is transferred to the garment, with a brilliant effect, somewhat similar to the colorful effect of the rainbow. In a dimmer environment with a little light, such as going to the bar or disco, there will be reflective colorful effect. These places wearing colorful reflective film transfer clothing, will certainly become the focus.

Laser film is a kind of printing film that has a sense of light, and is colorful and highly glossy. It is also a kind of PET film with great individuality.

Luminous film means that after absorbing enough light during the day, it can show a green glow at night. It mainly serves at night to attract attention and avoid collision.

High brightness reflective film is different from glow-in-the-dark film in that it reflects strong light when it is illuminated by light. This kind of printing film is suitable to be applied on the top of traffic management clothing, security clothing, and all kinds of clothing that need to be reminded.

Hot stamping film and silver hot stamping film is in line with some for clothing design has a high sense of luxury positioning. The main performance in the hot stamping film and hot stamping silver film in the transfer to the clothing, clothing design of the whole sense of light is very strong, high gloss. The whole person looks refreshed.

It has been said above that when distinguishing the choice of DTF film, it is necessary to pay attention to the observation of the coating. The following will describe what other points to pay attention to in addition to the coating part.

Can the PET printing film absorb ink normally without flowing around or not absorbing ink? In addition, can it do normal shaking powder, the quality of PET film can do outside the print area will not have hot melt powder residue. At the same time, in the case of cooling tearing film or hot tearing, whether there will be stuck, not smooth. If it is easy to tear the film, it proves that the quality is good. Finally, under normal storage conditions, there is no return of oil for a long time.

To summarize, choosing the consumables for DTF printer—PET film is not a very simple thing, and the bad use of consumables will also affect the printing effect very much. So it is very important to choose the right DTF film, if you are interested in DTF extremely related derivatives, you can search SUBLISTAR to enter the official website and contact us!