Automation Trends in Telescopic Belt Conveyor Systems

The logistics and warehousing industry is undergoing a significant transformation as automation becomes an essential component of modern operations. Businesses are continuously seeking solutions that reduce labor costs, improve efficiency, and enhance workplace safety. One area that has seen notable advancements is conveyor systems, particularly telescopic belt conveyors, which are now being integrated with cutting-edge automation technologies to streamline loading and unloading processes.

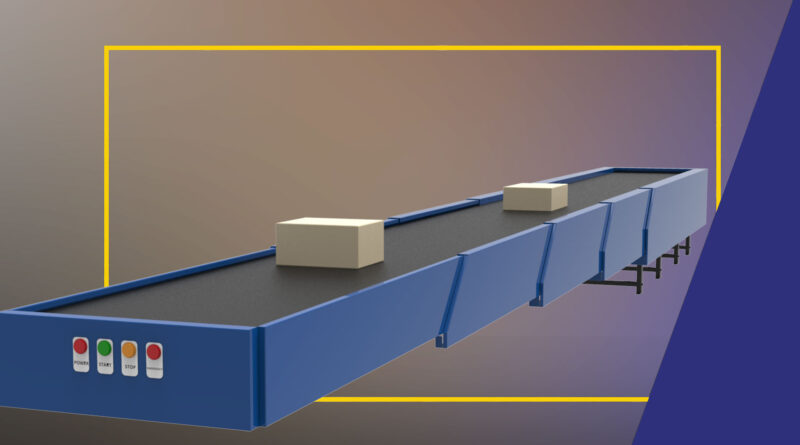

A telescopic belt conveyor is a type of conveyor system that extends and retracts to reach directly into trucks or containers, allowing for faster and safer material handling. Recent trends in automation have introduced features that go beyond simple extension and retraction, including smart sensors, motorized controls, and integration with warehouse management systems. These innovations are reshaping how facilities handle logistics, enabling faster turnaround times and reducing the dependency on manual labor.

Smart Sensors and Automated Controls

Modern telescopic conveyor systems increasingly rely on smart sensors to optimize operations. These sensors monitor package flow, detect blockages, and adjust belt speed automatically to prevent jams. By reducing human intervention, warehouses can achieve smoother material handling and fewer errors.

Automated controls allow operators to extend, retract, and adjust the conveyor with minimal effort. Some systems include remote monitoring and control panels, enabling staff to manage multiple conveyors from a central location. This level of automation improves operational efficiency and reduces the risk of accidents caused by manual handling.

Integration with Warehouse Management Systems

Automation trends are pushing telescopic belt conveyors to integrate more deeply with warehouse management software (WMS). By connecting the conveyor system to the WMS, businesses can track each package in real-time, optimize loading sequences, and manage priorities efficiently.

Integration with WMS also allows for predictive maintenance alerts. The system can monitor motor performance, belt tension, and other mechanical components, notifying maintenance teams before issues escalate. This proactive approach reduces downtime and keeps operations running smoothly.

Variable Speed and Load Sensing Technology

Newer telescopic belt conveyor systems often include variable speed settings and load sensing technology. Variable speed allows the belt to adjust automatically based on package size, weight, or flow rate. This flexibility reduces the risk of damage to packages and enhances the efficiency of high-volume operations.

Load sensing technology detects the presence and weight of items on the belt, adjusting conveyor speed or stopping the belt when necessary. By managing package flow dynamically, warehouses can maintain consistent throughput and improve overall operational reliability.

Energy Efficiency and Eco-Friendly Design

Automation trends are also driving energy efficiency in telescopic conveyor systems. Intelligent motor control and energy-saving components reduce power consumption without compromising performance. Some systems now include regenerative braking, which converts kinetic energy back into electrical energy during belt deceleration.

Eco-friendly designs help companies meet sustainability goals while lowering operational costs. Reduced energy usage not only benefits the environment but also contributes to the overall efficiency and profitability of warehouse operations.

Safety Enhancements through Automation

Automated telescopic conveyors are improving workplace safety by minimizing manual handling and exposure to hazards. Safety features such as emergency stop buttons, collision sensors, and automated braking systems prevent accidents and protect workers.

Automation also reduces fatigue among employees, as they no longer need to manually push or pull heavy packages. Ergonomic benefits combined with smart safety measures contribute to healthier and more productive working conditions.

Robotics Integration and Future Trends

The future of telescopic belt conveyor automation is closely tied to robotics. Robotic arms and automated guided vehicles (AGVs) can work alongside telescopic conveyors to handle loading, unloading, and sorting tasks. This level of integration allows warehouses to operate almost entirely autonomously, increasing throughput and minimizing human error.

Artificial intelligence (AI) is also being incorporated into conveyor systems. AI algorithms can predict peak loading times, optimize package flow, and even detect irregularities in packaging or weight. Such advanced automation trends are set to revolutionize warehouse logistics and set new standards for efficiency and safety.

Predictive Maintenance and Analytics

Automation is not limited to operational tasks; it also enhances maintenance practices. Modern telescopic belt conveyor systems collect data on motor performance, belt wear, and operational hours. Predictive analytics can then identify patterns that indicate potential failures, allowing maintenance teams to act before a breakdown occurs.

This approach minimizes downtime and reduces repair costs, ensuring that conveyor systems remain reliable and productive over the long term. Data-driven maintenance is becoming a critical component of automated warehouse management.

Conclusion

Automation trends in telescopic belt conveyor systems are reshaping the logistics landscape. From smart sensors and variable speed belts to robotics integration and predictive maintenance, these innovations improve efficiency, reduce labor costs, and enhance safety.

As warehouses continue to adopt advanced automation technologies, telescopic belt conveyors will play a central role in creating faster, safer, and more sustainable material-handling operations. Embracing these trends allows businesses to stay competitive in an increasingly fast-paced and demanding supply chain environment.